Imagine adjusting your clothes to beat the summer heat or winter chill just by changing the temperature of your clothes, on the go. Wearable thermal control devices promise just that, offering portable personal thermal comfort. Not only that, but these devices also have other applications such as providing temperature feedback in virtual and augmented reality and offering thermotherapy for heat issues among others. Consequently, researchers have been thoroughly exploring different types of wearable thermal devices. In particular, soft robotics and liquid-cooling garments stand out for their ability to naturally conform to the human body.

Liquid cooling garments, already used for race car drivers, surgeons, chemotherapy, multiple sclerosis patients, and athletes, employ tubes embedded in clothes to circulate cool or warm liquids via a pump to change body temperature. However, providing power to these systems requires bulky and noisy equipment, making them cumbersome. Recently, the electrohydrodynamic (EHD) pump, which pumps liquids by injecting charges inside a liquid and moving them by using an electric field, has been gaining attention for wearable devices. The EHD pump is silent, lightweight, and offers higher flow rates than other pumps. Combining EHD pump with soft tubes, which easily conform to the human body, offers a unique opportunity for compact and silent wearable thermal control devices. However, these soft tubes can experience blockages due to bending, necessitating real-time flow-rate monitoring and thus requiring additional equipment and power sources.

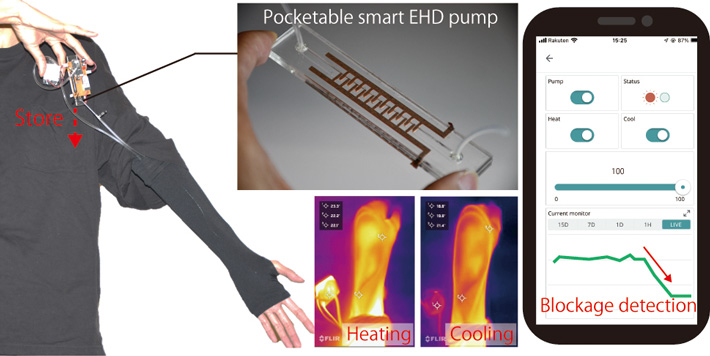

Addressing this issue, a team of researchers from Japan, led by Ph.D. student Yu Kuwajima from the Department of Engineering Science and Mechanics at the Shibaura Institute of Technology, has developed an innovative new Pocketable and Smart Electrohydrodynamic Pump (PSEP) for clothes. "Our innovative device, with its compact and stylish design, breaks the constraints of size and appearance associated with traditional wearable cooling and heating devices, while its self-sensing capability to monitor flow rates enhances system reliability without the need for any additional equipment," explains Mr. Kuwajima. The team included Yuhei Yamada and Shingo Maeda from Tokyo Institute of Technology, Naoki Hosoya from the Shibaura Institute of Technology, and Yasuaki Kakehi from the University of Tokyo. Their study was made available online on December 14, 2023, and published in Volume 16, Issue 1 of the journal ACS Applied Materials & Interfaces on January 10, 2024.

A key innovation of PSEP is the model for self-sensing of flow rates in EHD pumps. This self-sensing model uses the changes in current between the electrodes of the PSEP to measure the flow rate. If any load changes the flow rate, the current through the electrodes changes. This change in current can then be used to measure the flow rate within the device itself. The team experimentally validated their model and found that the results were consistent with their theoretical calculations. Moreover, their testing revealed that the PSEP can adjust temperatures by up to 3 °C, significantly enhancing personal comfort.

Using this model, the team constructed a compact PSEP device that fits into a regular shirt pocket, offering stylish and discreet thermal control. Additionally, it features an intuitive smartphone interface for seamless wireless control and monitoring. Furthermore, its ability to detect and notify users of blockages, through self-sensing, ensures efficient operation and long life. In future, the team plans to integrate technologies such as self-healing liquids and advanced materials into PSEP to improve its resilience.

"Next-generation wearable tech has the potential to go beyond mere gadgets and truly transform our lives," says Mr. Kuwajima, emphasizing the importance of this study. "The key lies in achieving both miniaturization and advanced functionality. Our research marks the beginning of this exciting journey, paving the way for a future where technology seamlessly integrates into our daily routines, making them richer and more comfortable."

Overall, this study marks a significant step forward in the field of wearable devices and can inspire innovative personal thermal control devices!

. Any information published on this site will be valid in relation to Science Tokyo.