Energy-efficient green route to magnesium production: Improved Generation Efficiency Using Antenna Structure

Through a collaborative research program funded by Oricon Energy Inc., the research group of Professor Yuji Wada and Adjunct Professor Satoshi Fujii of the Tokyo Institute of Technology, School of Materials and Chemical Technology devised a magnesium smelting method that uses nearly 70% less energy than conventional methods by using microwaves.

Oxide (dolomite: MgO, CaO), which is a raw material for magnesium metal, does not absorb microwave energy well and does not generate heat. This time, when electrically conductivity ferrosilicon (FeSi) used as a reducing agent was mixed with the raw dolomite material and made into an

antenna1 structure, it became easier to absorb the microwave energy and reduce the temperature. Internal heating and contact point heating, which are microwave characteristics, were observed, and the average reaction temperature for this smelting was lowered from the conventional 1,200 - 1,400°C to 1,000°C.

This research result was published in the April 12th issue of "Scientific Reports," the online edition of the sister magazine of the UK scientific journal Nature.

Research Highlights

- Developed a new smelting method for magnesium, which is the lightest industrial-used metal

- Devised a forming method for materials to improve thermal conductivity during microwave irradiation

- Expected to result in energy savings for smelting other useful metals

Background

Currently, the smelting of magnesium metal is mainly performed using the Pidgeon method (thermal reduction method) where the material temperature is raised using a large amount of coal as the heat source. About 80% of magnesium metal is produced in China. A large amount of coal is consumed for smelting, resulting in the generation of the air pollutant PM 2.5 (fine particulate matter) and the release of carbon dioxide to the atmosphere, which are major problems.

The Pidgeon method is a technique for heating dolomite ore and silicon iron to high temperatures and then cooling the evaporated magnesium to obtain magnesium metal.

2MgO (s) + 2CaO (s) + (Fe)Si (s) → 2Mg (g) + Ca2SiO4 (s)+ Fe (s)

- *

- s: Solid, g: Gas

Dolomite mineral: MgO, CaO; Ferrosilicon: FeSi

Heat source: Coal

Research Achievements

Normally, dolomite is a poor absorber of microwave energy and does not generate heat. However, by using ferrosilicon as the reducing agent, devising the shape of the raw material pellet obtained by mixing dolomite and ferrosilicon and forming it as an antenna so that it has a resonance structure of 2.45 GHz (same as the frequency for microwave ovens), it was possible to confine the microwave energy to the pellet.

In a small-scale experimental reactor, 1 g of magnesium metal was smelted successfully. Also, in order to accurately estimate the energy, a demonstration furnace about 5 times larger than the experimental furnace was produced and experiments were conducted, resulting in the successful smelting of about 7 g of magnesium metal. This can reduce energy by 68.6% compared with the conventional method.

Future Developments

This success in saving energy for smelting magnesium metal has led to the possibility of this technique being developed and applied to the high temperature reduction process of oxides. In the future, through further development of this research, it will be applied to the smelting of other metal materials to save energy with steel, metals, materials, and chemistry, which have not advanced, and help reduce carbon dioxide, which is one of the causes of global warming.

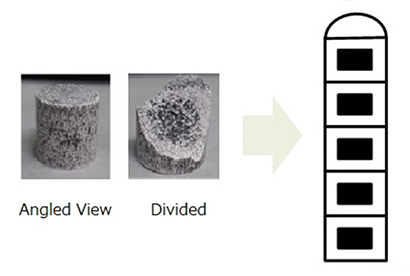

Figure 1. Fabrication of antenna structure using dolomite and ferrosilicon

(left) Actual pellet of dolomite and ferrosilicon. White portion is dolomite rich, and the black portion is ferrosilicon rich. Ferrosilicon is concentrated in the center portion.

(right) Five stacked to form the microwave wavelength (antenna structure).

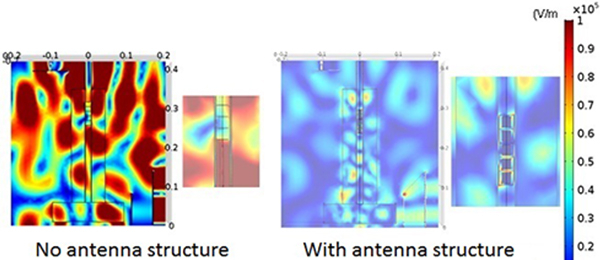

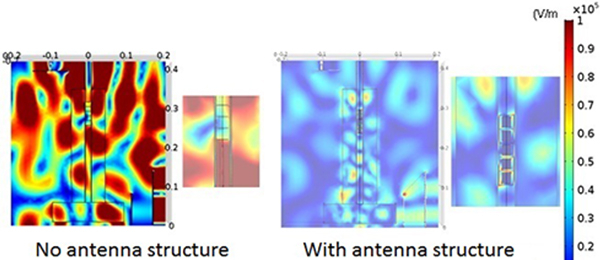

Figure 2. Difference in the distribution of the electric field in the applicator with and without the antenna structure through simulation.

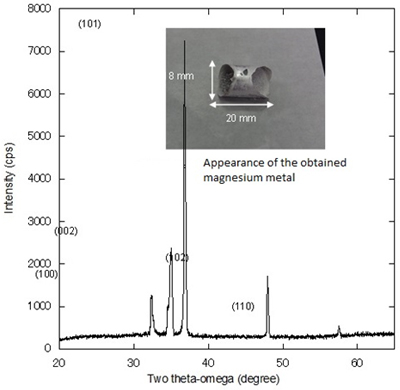

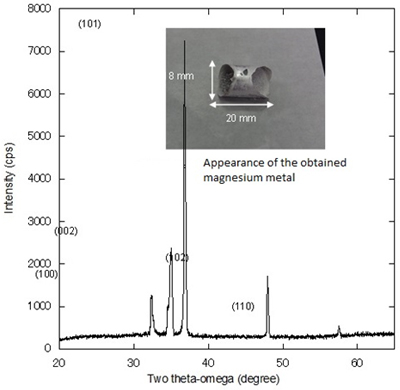

Figure 3. Result of magnesium smelting in small furnace

X-ray diffraction result of the obtained magnesium metal. Magnesium peak is observed.

1 Antenna

The simplest is an electric conductor (monopole antenna) with a wavelength of radio waves / 4 that resonates at an integral multiple of this. The role of an antenna is to take in the energy from a space to the inside. Generally, antennas are mounted to communication devices such as cellular phones, and are used to extract digital information contained in radio waves.

Reference

Authors: |

Yuji Wada1, Satoshi Fujii1,†, Eiichi Suzuki1, Masato M. Maitani1,‡, Shuntaro Tsubaki1, Satoshi Chonan2, Miho Fukui2 & Naomi Inazu1 |

Title of original paper: |

Smelting Magnesium Metal using a Microwave Pidgeon Method |

Journal: |

Scientific Reports |

DOI: |

|

Affiliations: |

1Department of Applied Chemistry, Graduate School of Science and Engineering, Tokyo Institute of Technology

2Oricon Energy Inc.

†Present address: Department of Information and Communication System Engineering, National Institute of Technology, Okinawa College

‡Present address: Research Center for Advanced Science and Technology, The University of Tokyo

|

. Any information published on this site will be valid in relation to Science Tokyo.