An integrated FPGA fit for AI

LSIs are increasingly required to process large amounts of data at high speed using AI. Under these circumstances, development is underway of a rewritable LSI, called a field-programmable gate array (FPGA), that is fit for AI.

An FPGA stands out for allowing the user to freely reconfigure the circuit according to the application. With the rapid spread of AI in recent years, Associate Professor Hiroki Nakahara (Tokyo Institute of Technology) is working on the development of FPGA implementation technology that is optimal for AI deep learning and machine learning, as well as design methods and tools for AI to efficiently process data using an FPGA.

"Currently, AI data processing capacity is doubling per year. If this capacity increases by ten times its current value, it will perhaps be on par with the human brain.[Ref. 1] I expect that it will become reality within three to four years," said Nakahara.

Pursuing this, in recent years there has been robust research and development of dedicated AI CPUs.

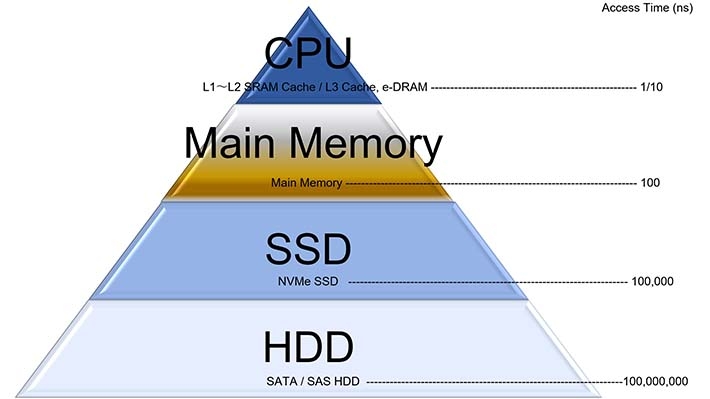

Nakahara continues, "AI processing makes predictions by repeating multiply-accumulate operations one trillion or ten trillion times on input data while reading training data. Therefore, increasing the number of memories to store more training data and increasing the number of multiply-accumulate operation circuits inside the CPU improve the processing power of AI. However, the amount of data processed by AI has increased dramatically, and in order to process it in real time, we have no choice but to increase the number of arithmetic circuits, and the scale of CPUs tends to increase."

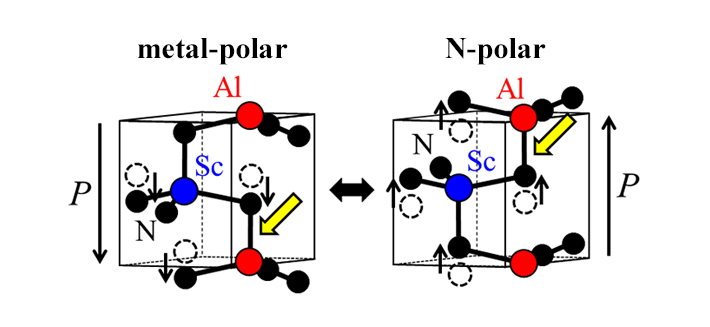

Instead of relying on existing CPUs, Nakahara focused on the flexibility of FPGAs, which allow the circuits to be freely rewritten. He developed a calculation method that can express the values "-1", "0" and "1" with 2 bits. Based on this, he invented a technology that can express in 2 bits calculations that required 32 bits with conventional CPUs. As a result, by implementing a circuit dedicated to ternary operations on the FPGA, he was able to significantly reduce the size without degrading the processing performance of the AI.

"Many attempts have been made in Japan and overseas to reduce the number of bits, but usually reducing the number of bits reduces the recognition performance of AI. However, my laboratory has technology to limit the deterioration of recognition performance, and that is our strength," states Nakahara.

He is also conducting research to reduce the amount of calculations of AI itself.

"AI processing is an addition and multiplication monster. Therefore, we are creating a dictionary to store the data, and store the calculation results in advance. As a result, calculations can be completed simply by referencing the dictionary, greatly reducing the amount of calculations. We were also able to overcome the problem of increasing the size of the dictionary by using ternary operations," explains Nakahara.

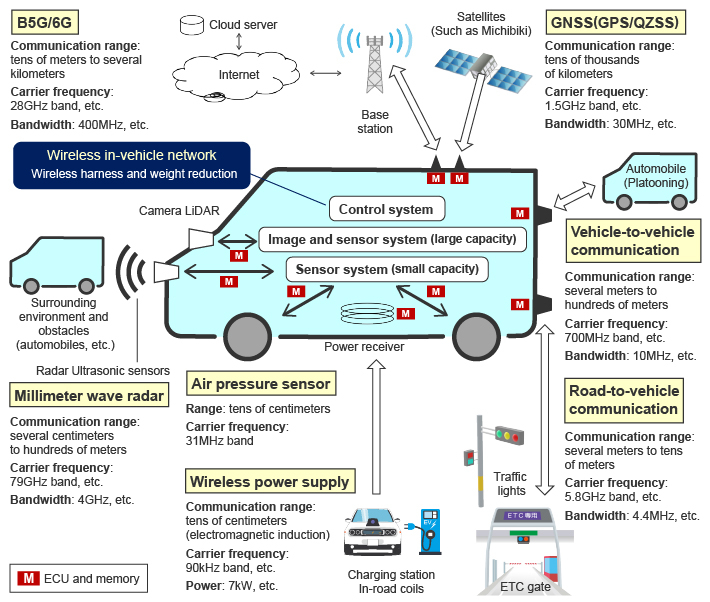

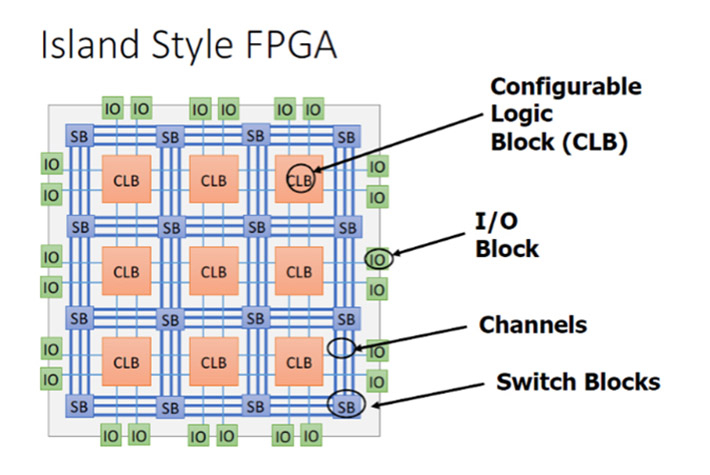

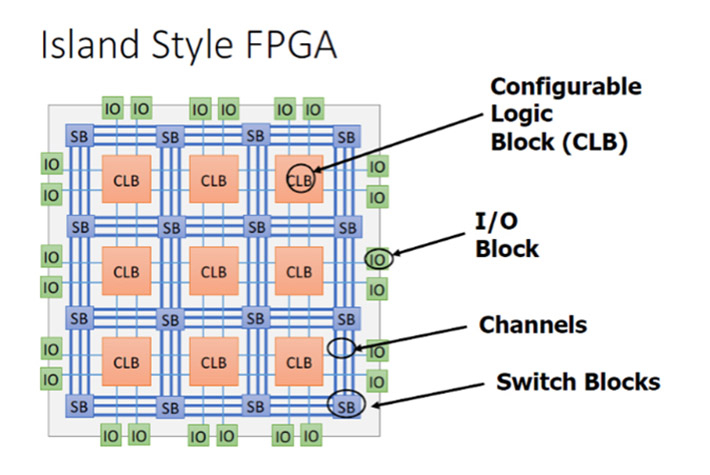

The figure below shows an FPGA with multiple dictionaries (the part labeled "CLB"). Which dictionaries to refer to and in what order can be set using a program. The advantage of FPGA is thus that an LSI circuit can be freely designed and changed according to the application.

Configuration of a typical FPGA. The configurable logic block (CLB) functions as a dictionary that stores data. A large number of CLBs are arranged in an island pattern, and connectable wiring surrounds the periphery of the CLBs. By configuring the wiring according to the design using a program that rewrites the FPGA, it is possible to set which CLBs are to be referenced and in what order.

"Even if AI evolves further moving forward, we can deal with it by simply rewriting the FPGA as necessary. FPGAs and AI are seemingly very compatible," says Nakahara.

In addition to the dictionary reference method, an algorithm called "pruning" is introduced to reduce unnecessary operations, which both improves processing speed and also reduces power consumption.

The strength of Nakahara's research group is thus that it is involved with everything from the development of theory and algorithms to circuit design to create them and implementation on FPGAs.

Establishment of a Tokyo Tech start-up

Leveraging this strength, Nakahara established the Tokyo Tech start-up Tokyo Artisan Intelligence (TAI) in March 2020. Currently, the company is engaged in the AI system implementation business using FPGA.

Nakahara describes, "currently, there is a growing need for cost reduction and safety improvement using AI image processing. TAI is promoting the introduction of AI in collaboration with customers in a wide range of fields, such as increasing productivity due to labor shortages in primary industries such as fisheries, preventing accidents at work sites, medical care, healthcare, and nursing care."

For example, in 2020, through joint development with Maruha Nichiro, we succeeded in reducing human error and cutting costs by automating the number of farmed fish using AI image processing.[Ref. 2]

In addition, TAI is also moving forward with its project of mass-producing FPGA systems for AI processing, aiming for a 2023 release.

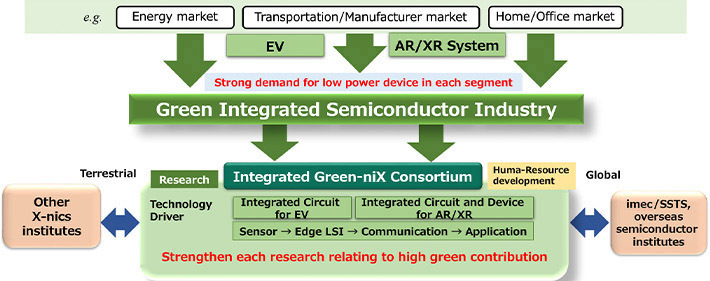

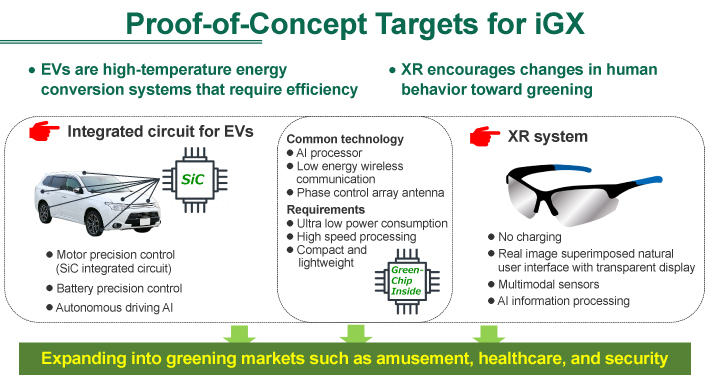

Improving the efficiency of AI calculation processing is indispensable in iGX's application fields of XR and EV. Therefore, Nakahara will continue to deepen exchanges with researchers and companies in various fields participating in the consortium, and plans to build a highly versatile next-generation FPGA platform that can be used to meet a wide range of needs.

- [Ref. 1] Jaime Sevilla, Lennart Heim, Anson Ho, Tamay Besiroglu, Marius Hobbhahn, Pablo Villalobos, Compute Trends Across Three Eras of Machine Learning, 9 Mar 2022, [2202.05924]

- [Ref. 2] Press release ."Sakurajima Fish Farm Co., Ltd. introduces AI tracking fish counter." Maruha Nichiro Corporation, May 18, 2020

. Any information published on this site will be valid in relation to Science Tokyo.